Overview:

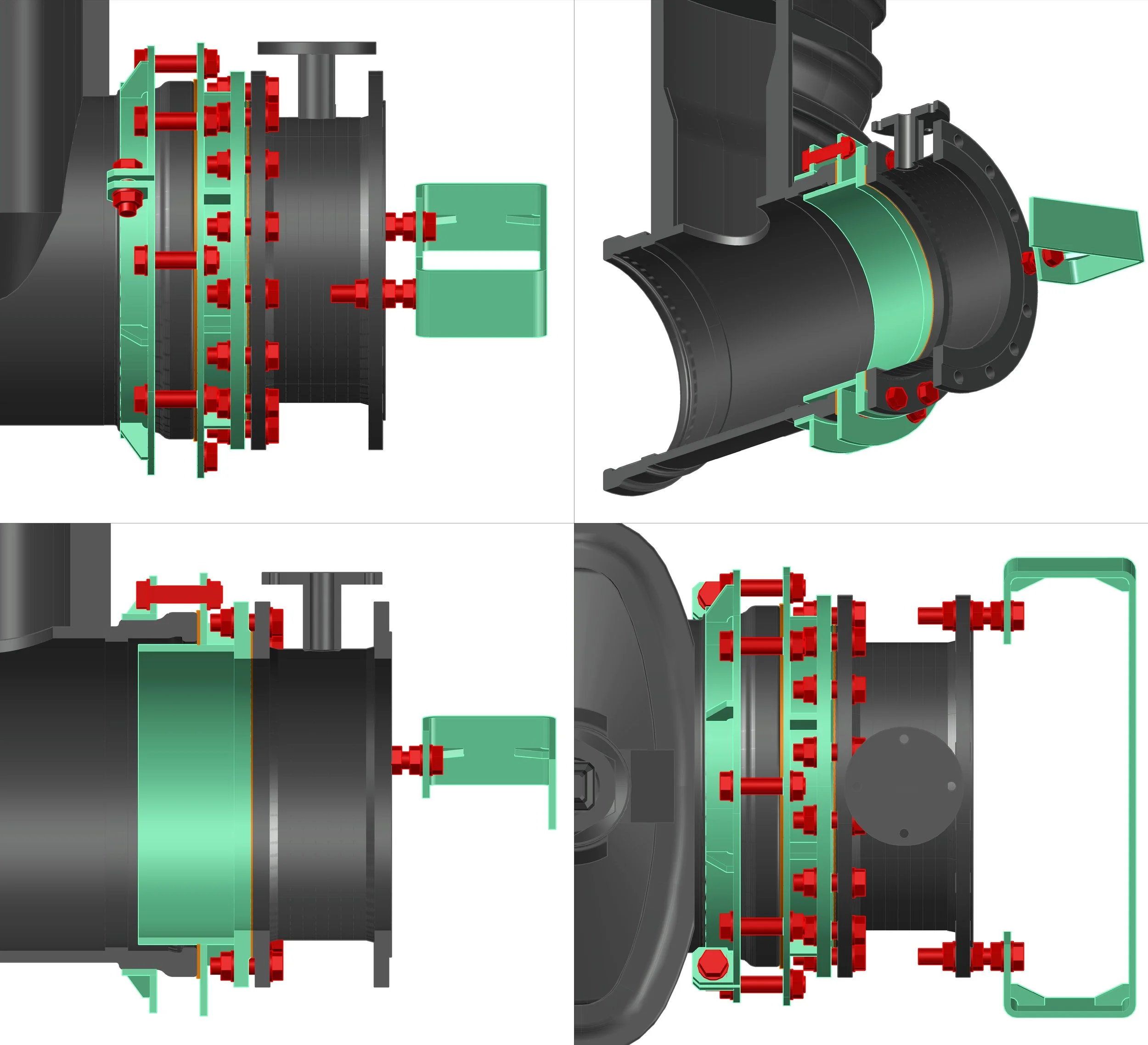

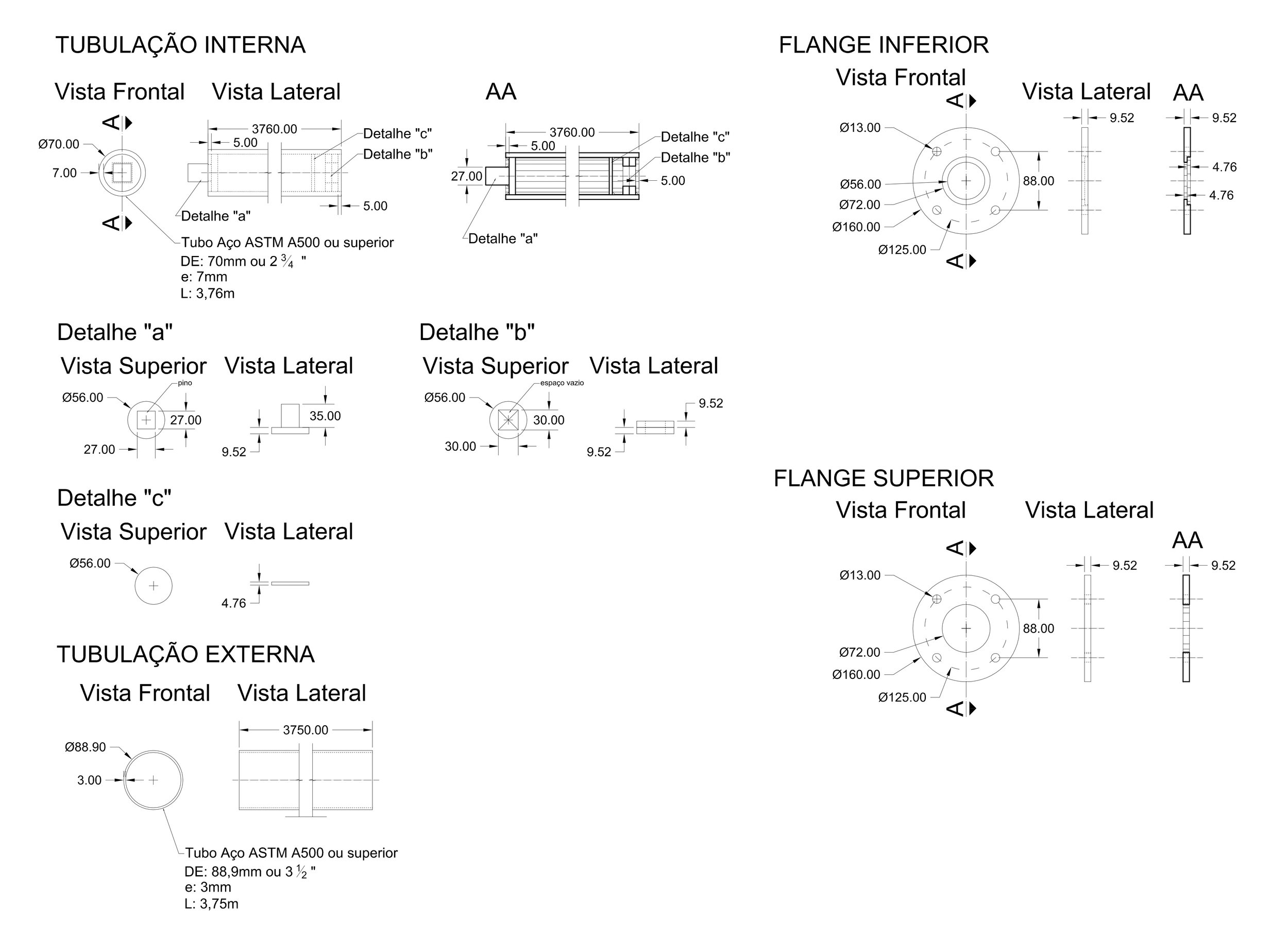

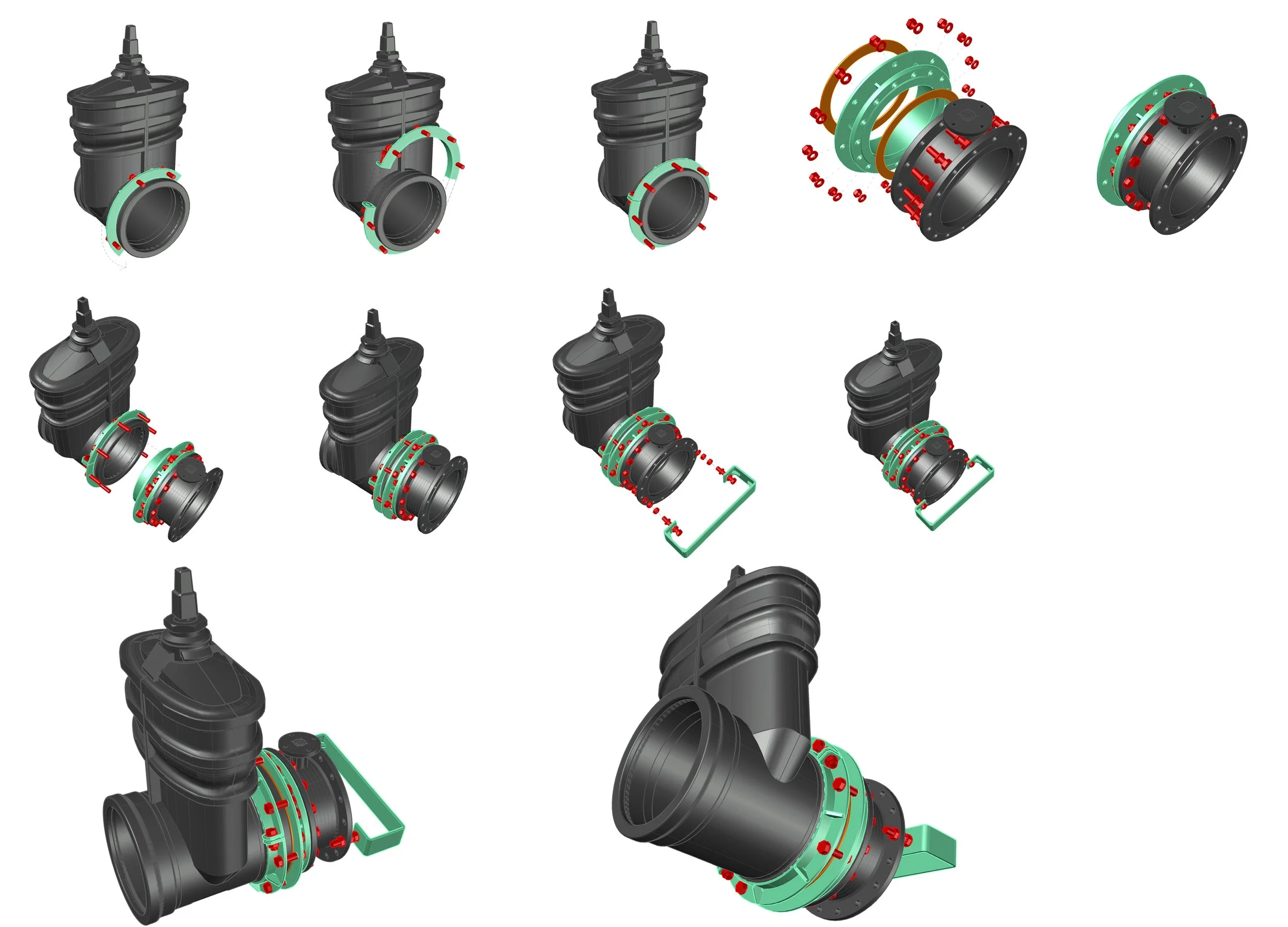

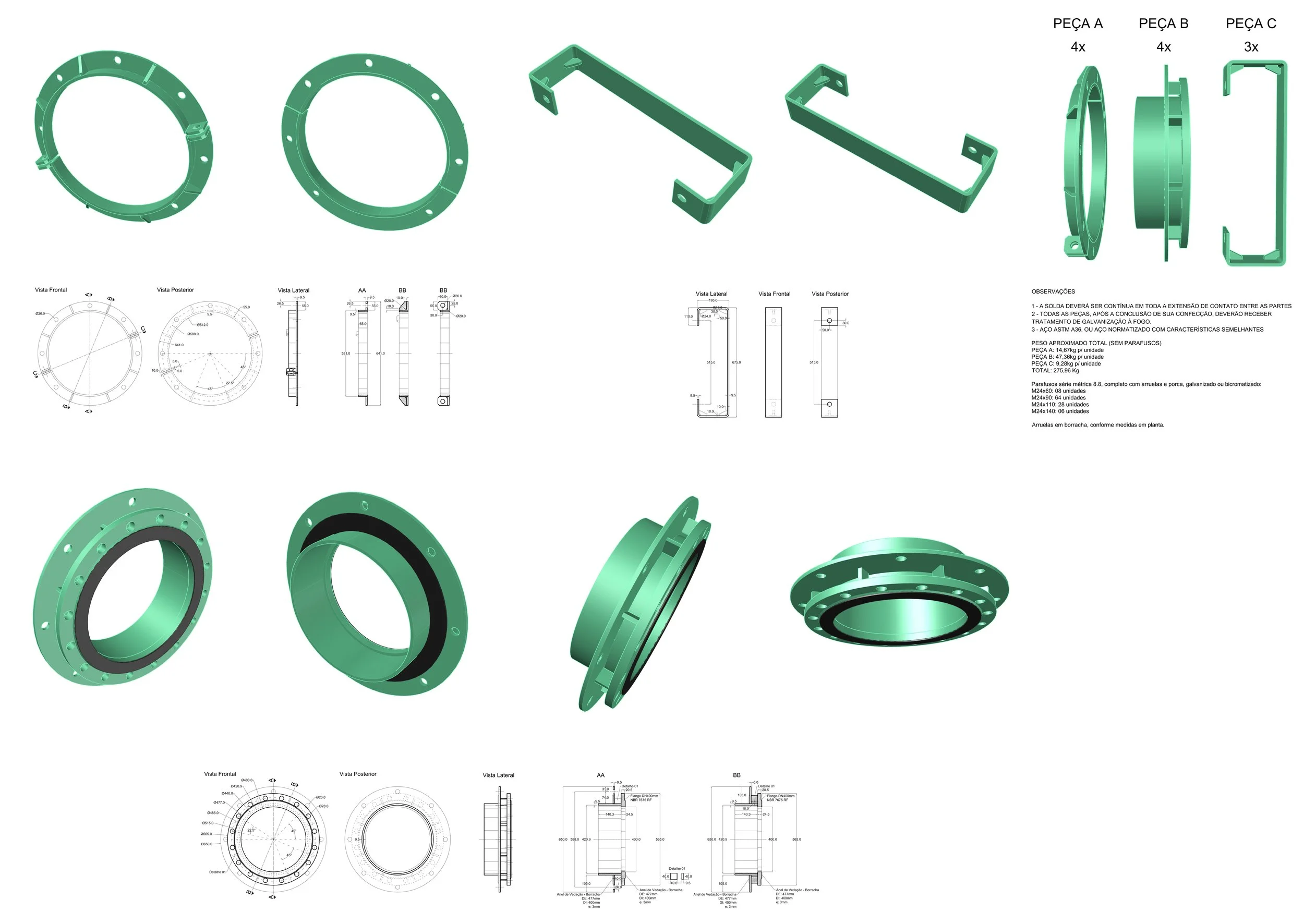

Several legacy discharge valves on the sedimentation units had lost sealing, causing persistent water losses at the water treatment station (WTS). A custom adaptor spool was designed to enable installation of a new set of butterfly valves, resolving leakage while improving controllability and maintenance. The first adaptor was installed personally to validate clearances, fit-up, and method, then the procedure was standardized for the team.

Challenges:

Shutting down the WTS, or even a single sedimentation unit, was not an option.

The 50+ year-old valves were severely damaged, and no spare parts were available

Differing fabrication standards prevented direct fit-up to existing interfaces, requiring a custom adapter.

Outcome and lessons learn:

Installing butterfly valves enabled smoother, more controlled discharge and allowed the use of a lower-cost pneumatic actuator compared with the existing gate valves.

After installation, operators performed decantation discharges more easily and reliably.