Overview:

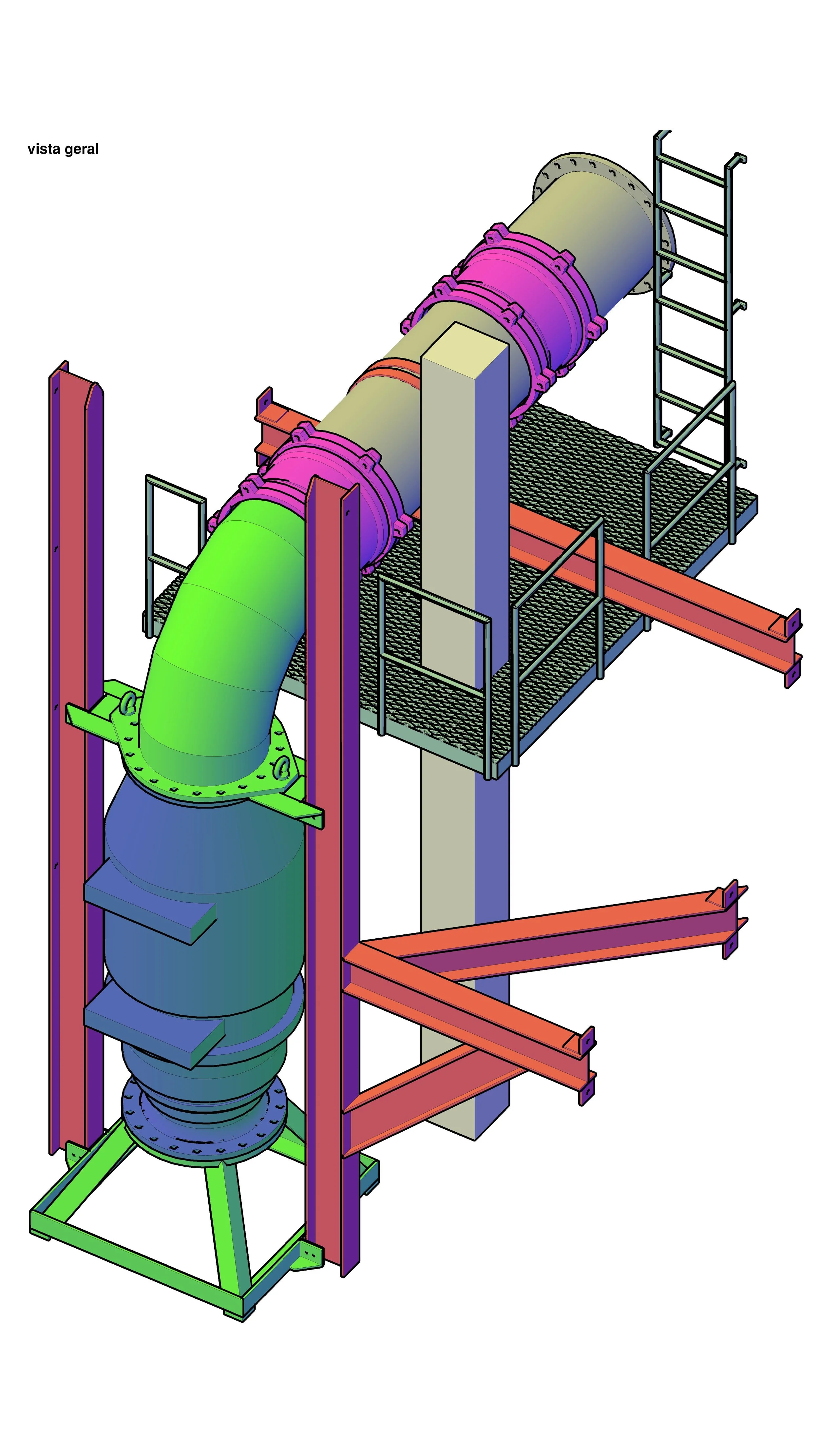

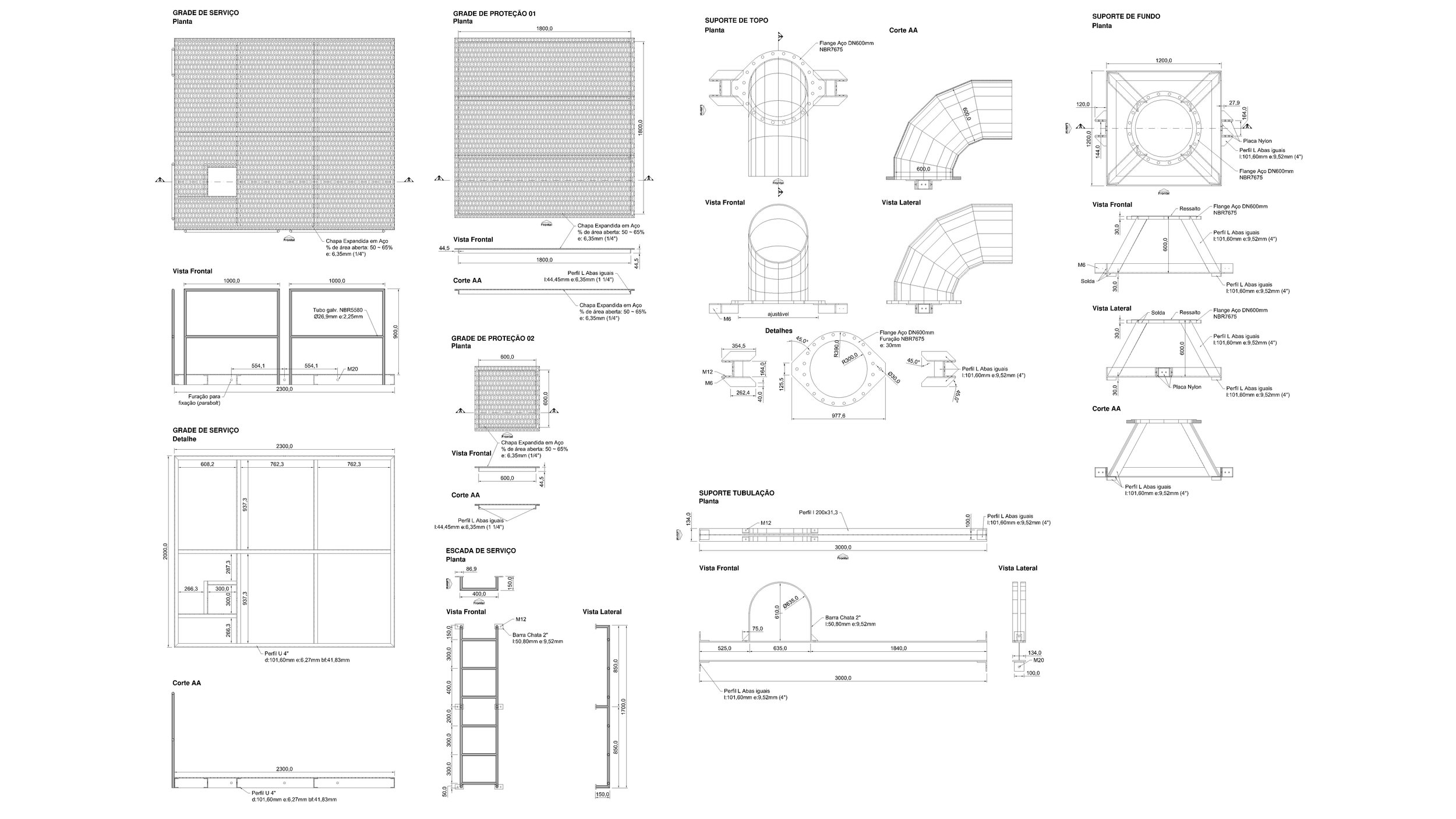

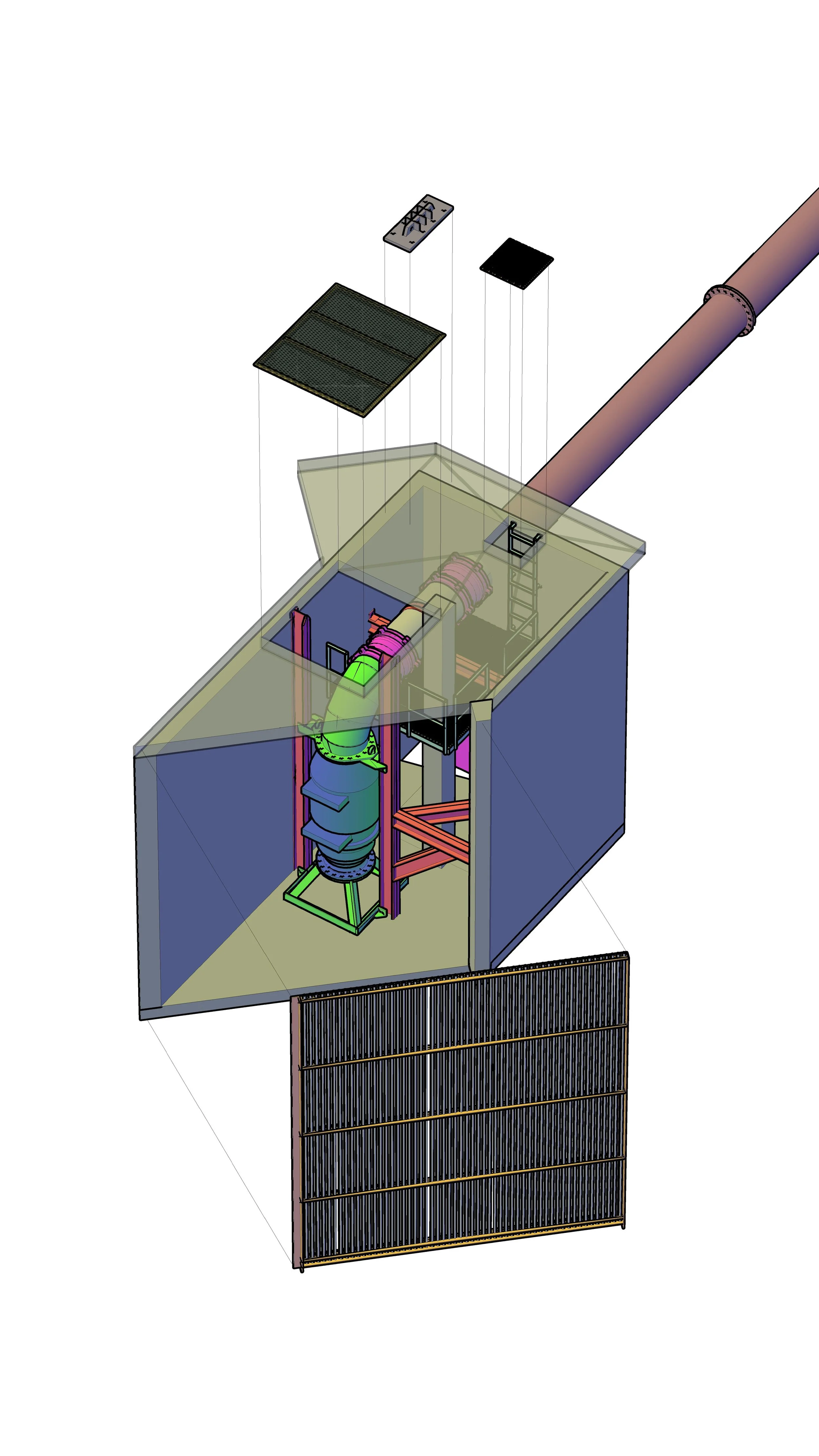

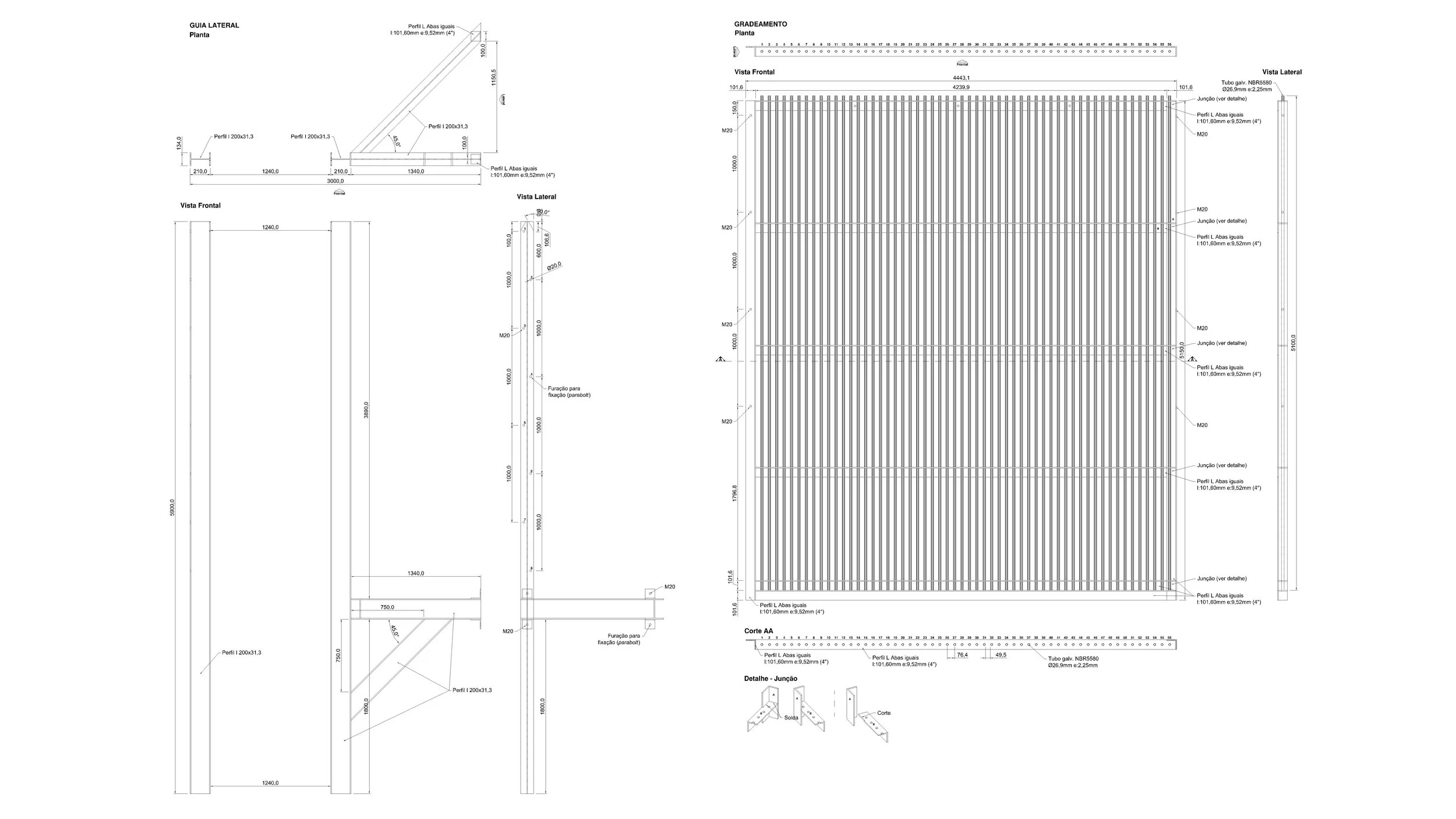

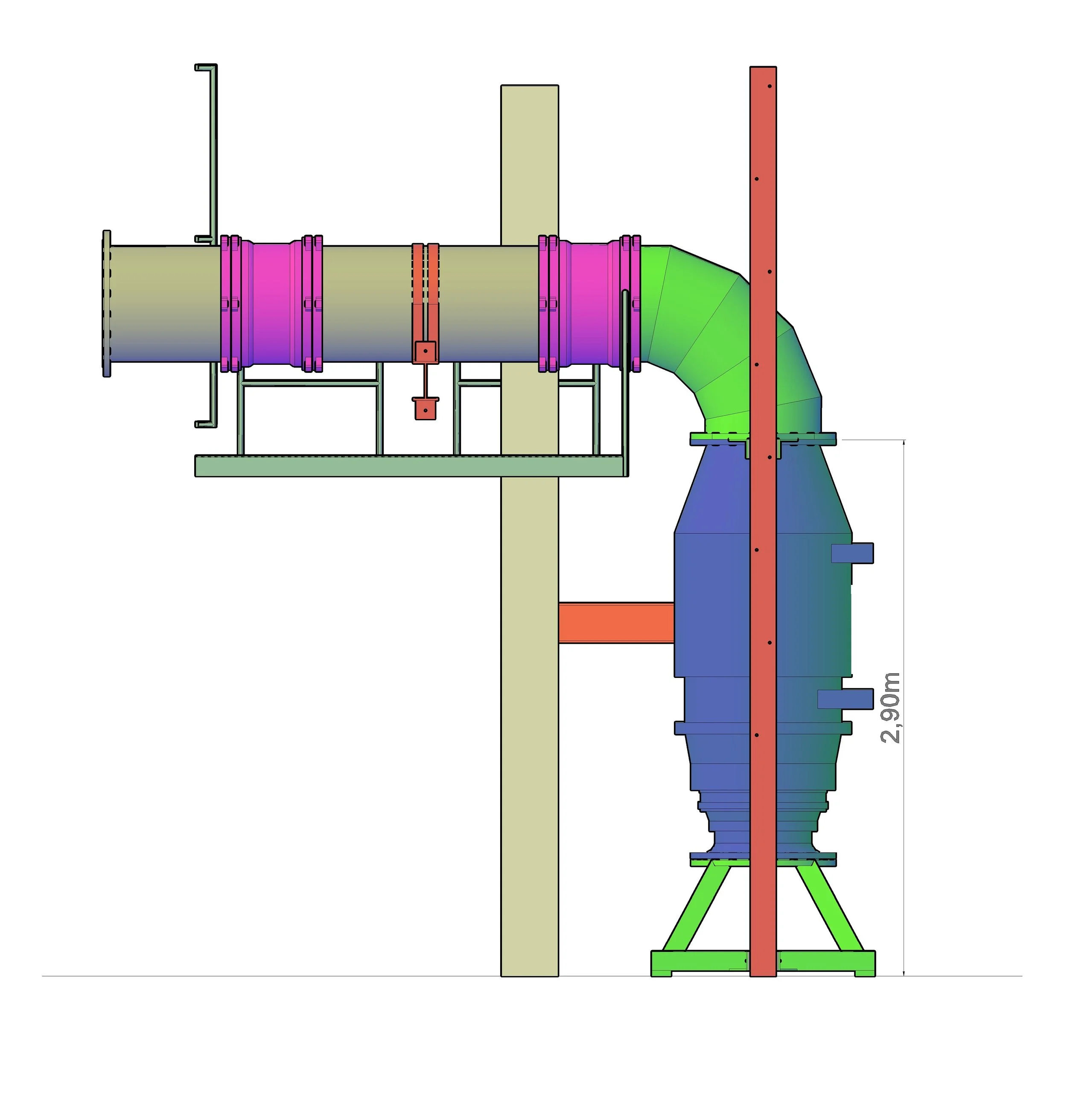

Installed a new submersible pump (~700 L/s) by retrofitting an existing concrete intake structure on the riverbank and connecting a DN 600 discharge to the raw-water line. Scope included civil modifications, pump mount and lifting points, discharge header and valves, electrical routing, and commissioning.

Challenges:

Large pump mass (~2.5 t) combined with unstable channel banks made new construction risky, so reusing the old intake channel was the safest, fastest option.

Outcome and lessons learn:

Because of the pump’s NPSH requirements, the channel water level must be monitored to prevent cavitation.