Overview:

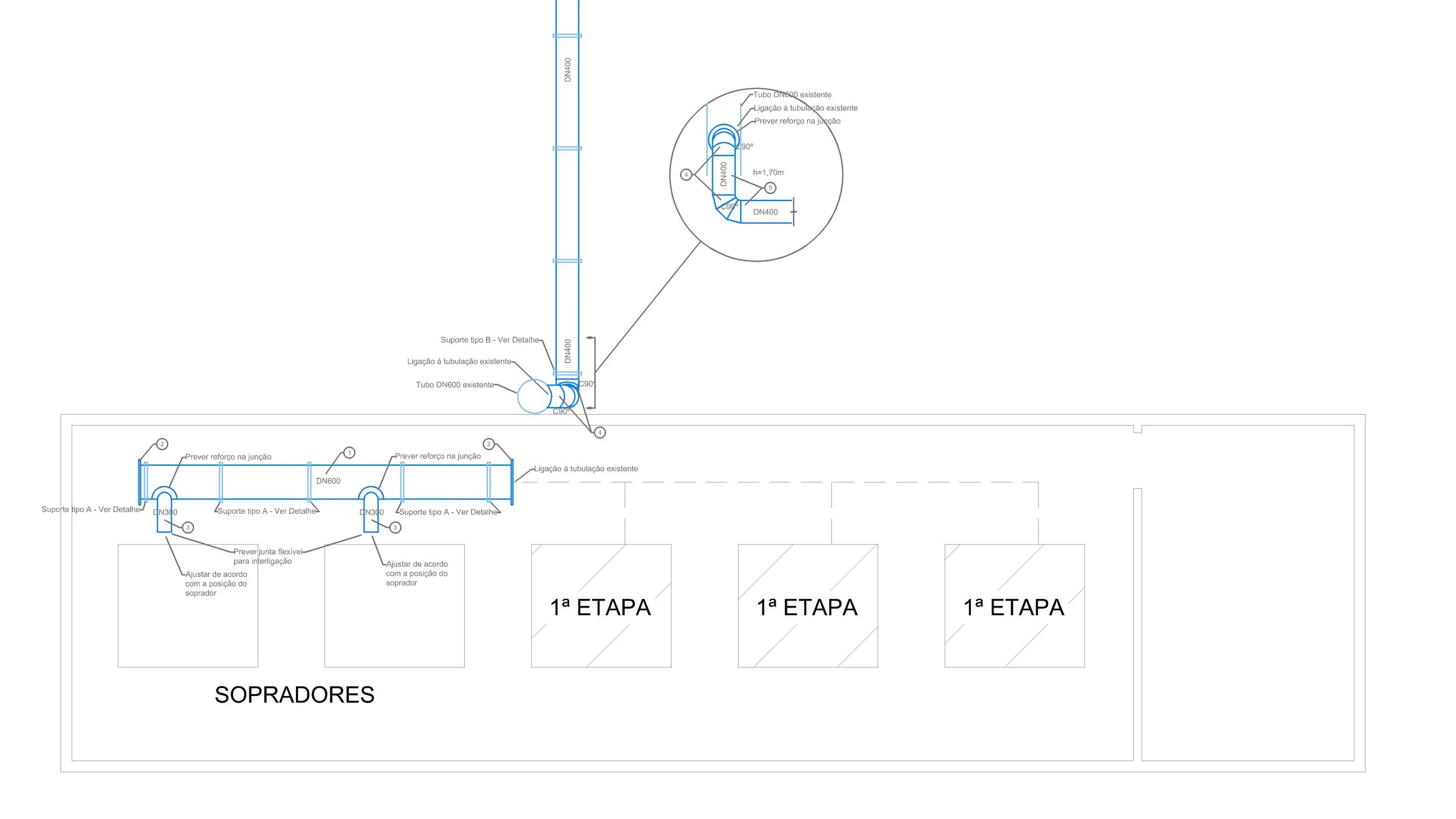

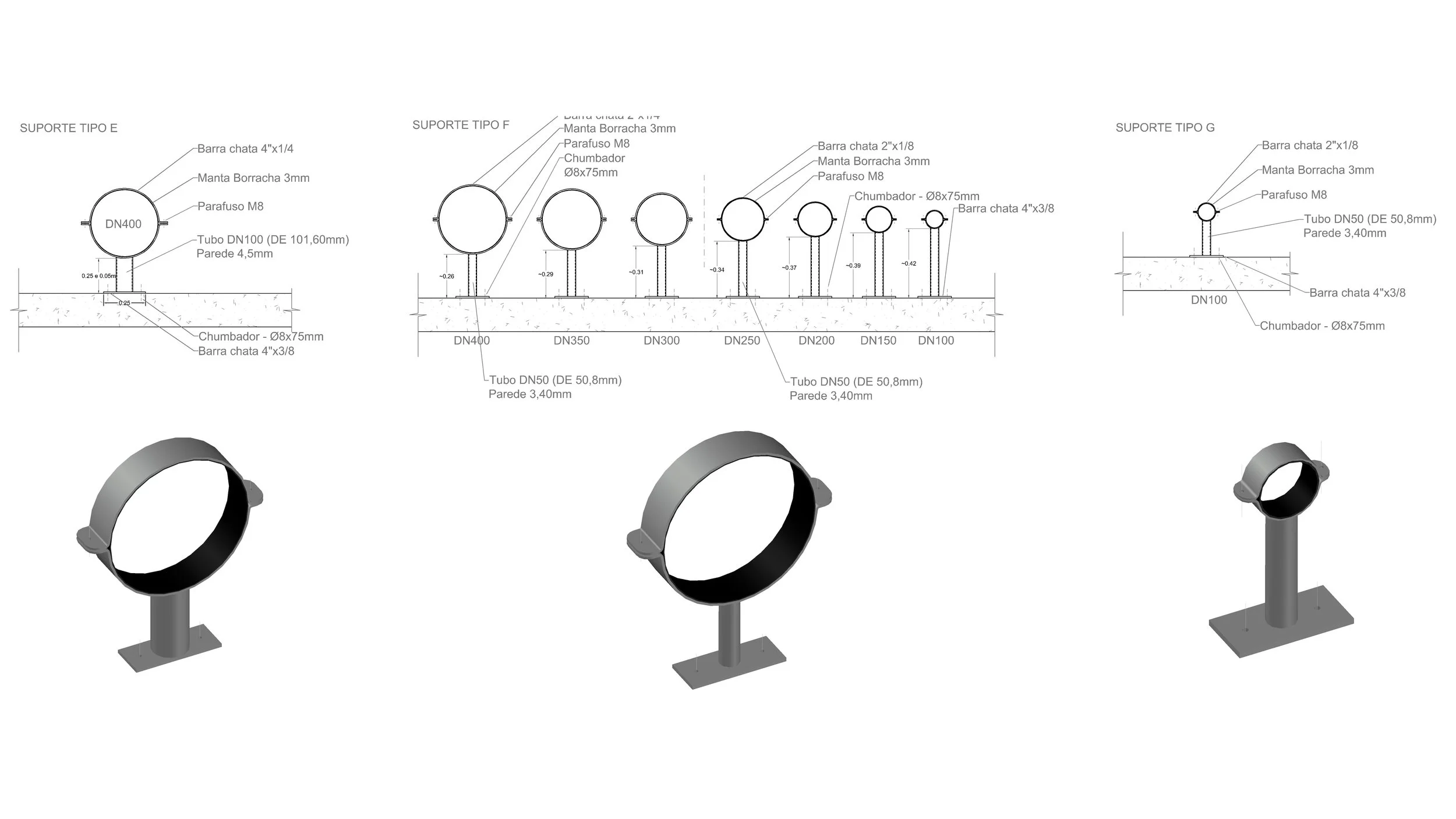

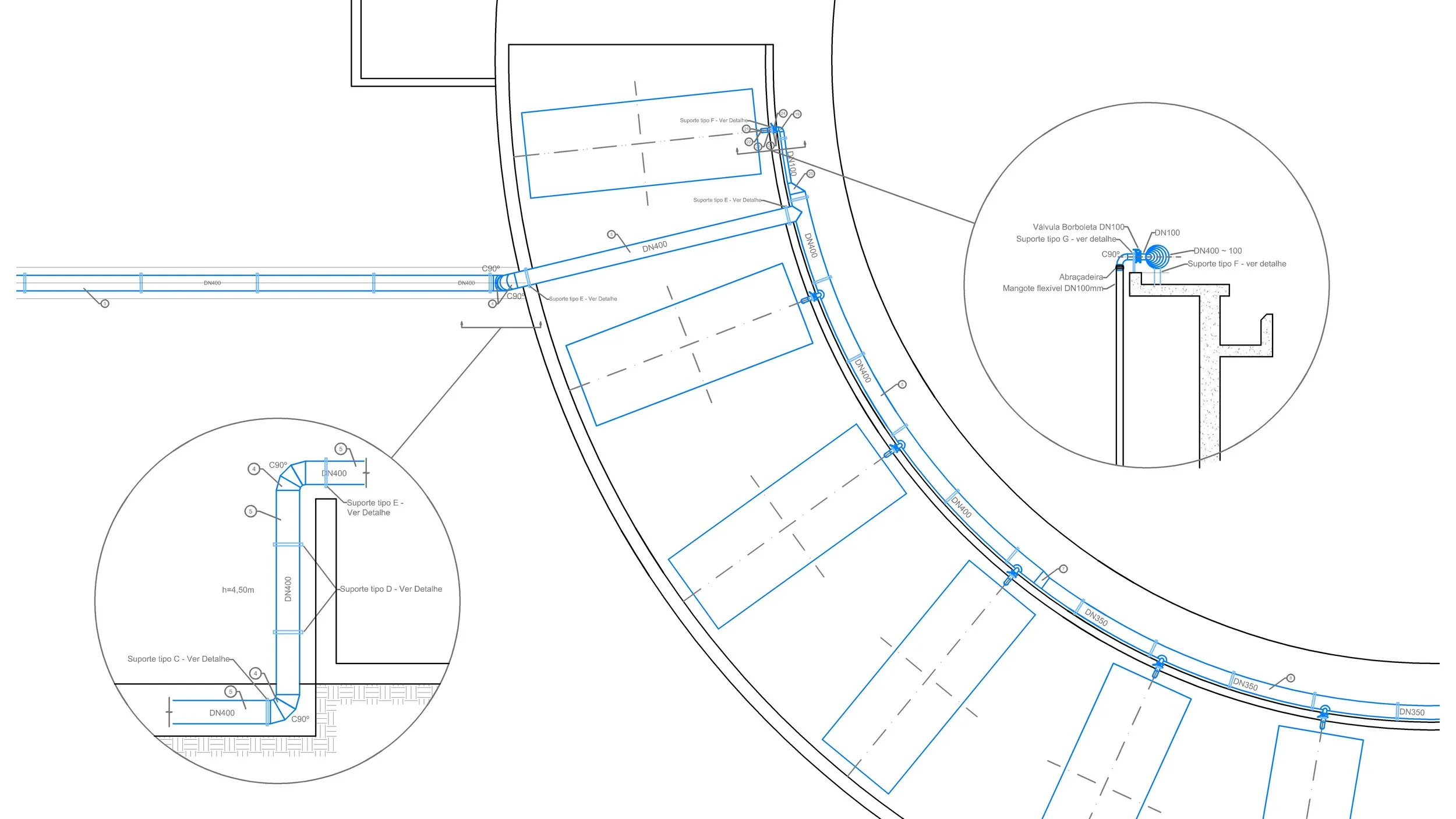

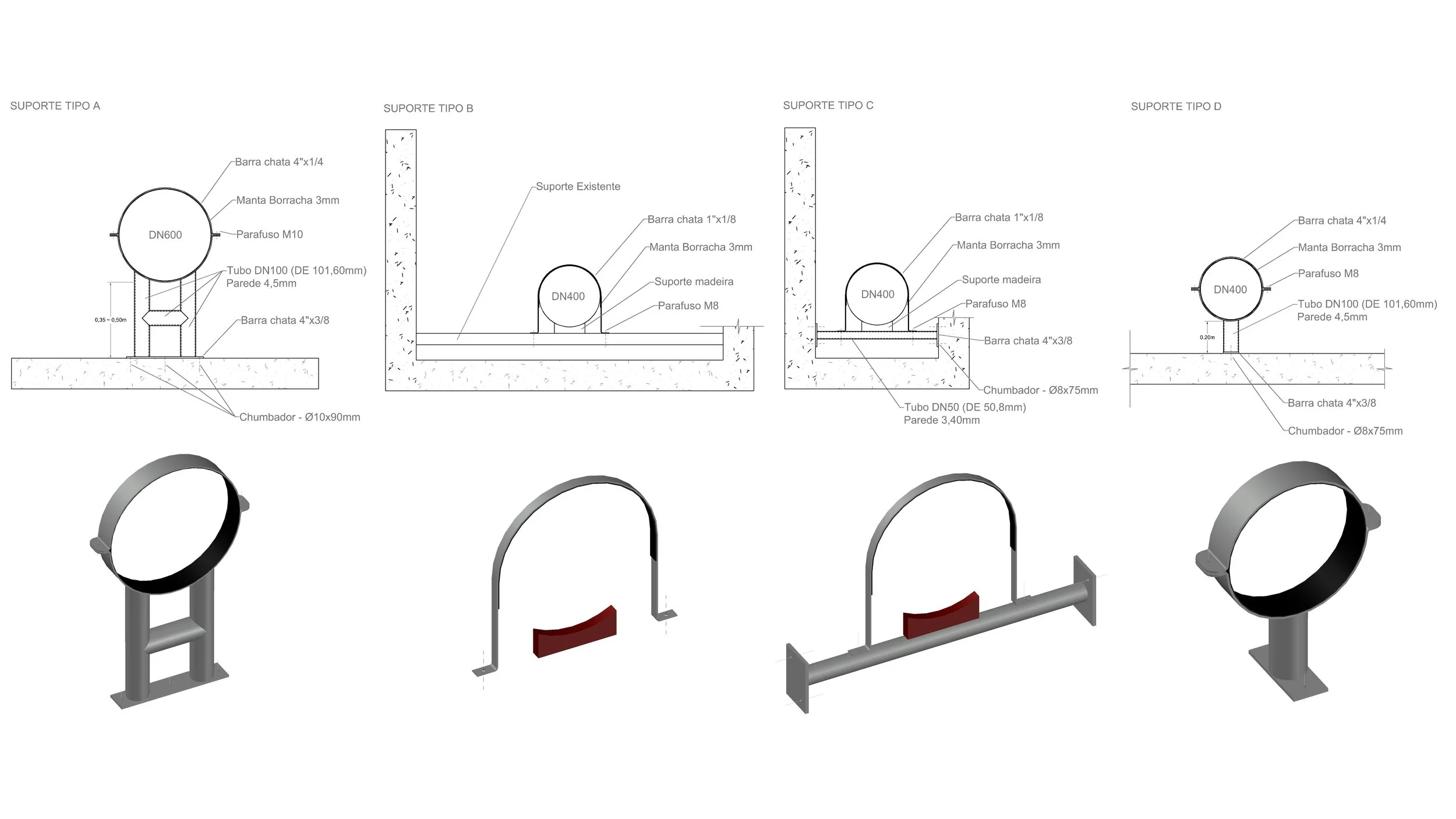

Designed, produced the full technical package, and supervised installation of a stainless-steel aeration air header and distribution piping (with supports) for a 130 L/s WWTS module. The scope included detailing supports and anchors, coordinating tie-ins to existing equipment, and planning staged works to maintain plant operations.

Challenges:

Integrated the new air header with Module I piping that was already in operation.

Executed blower tie-ins during a night shutdown within a short allowable outage window.

Outcome and lessons learn:

A main-header valve to balance air between modules would improve operations but was out of scope due to cost constraints.

Back-purging the stainless-steel pipe with inert gas (e.g., argon) during TIG welding is essential, improving weld root quality and extending system lifespan.