Overview:

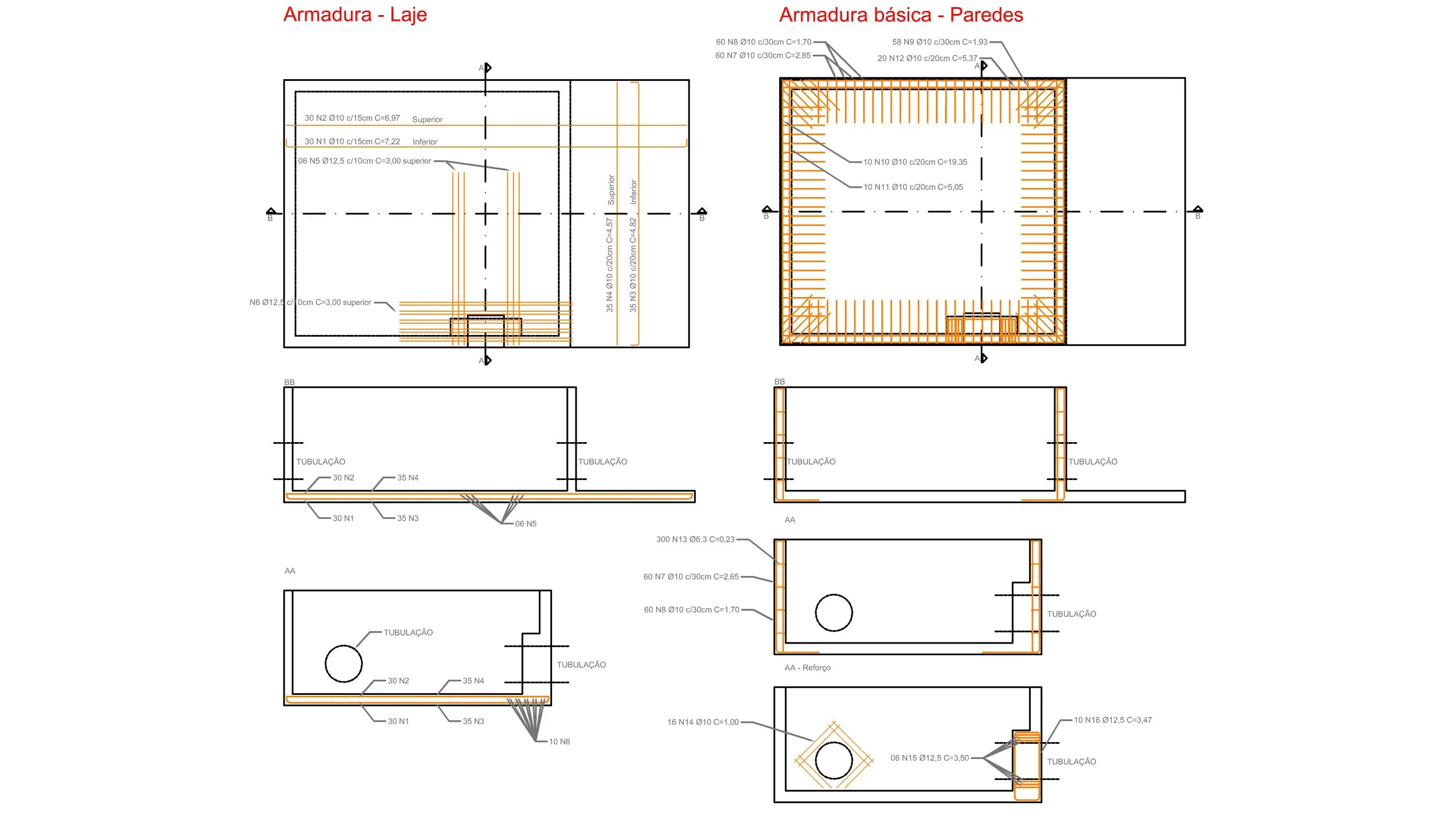

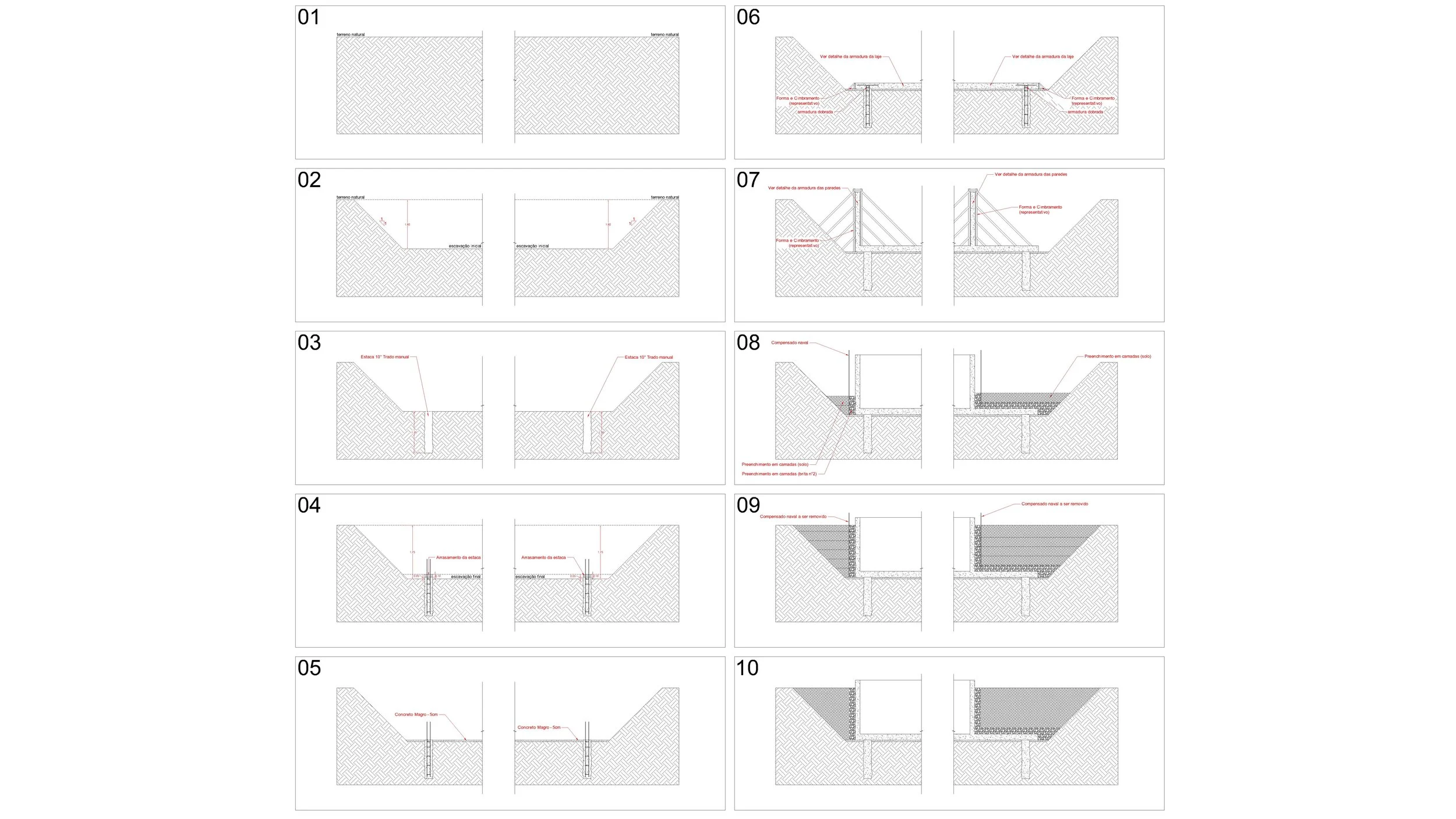

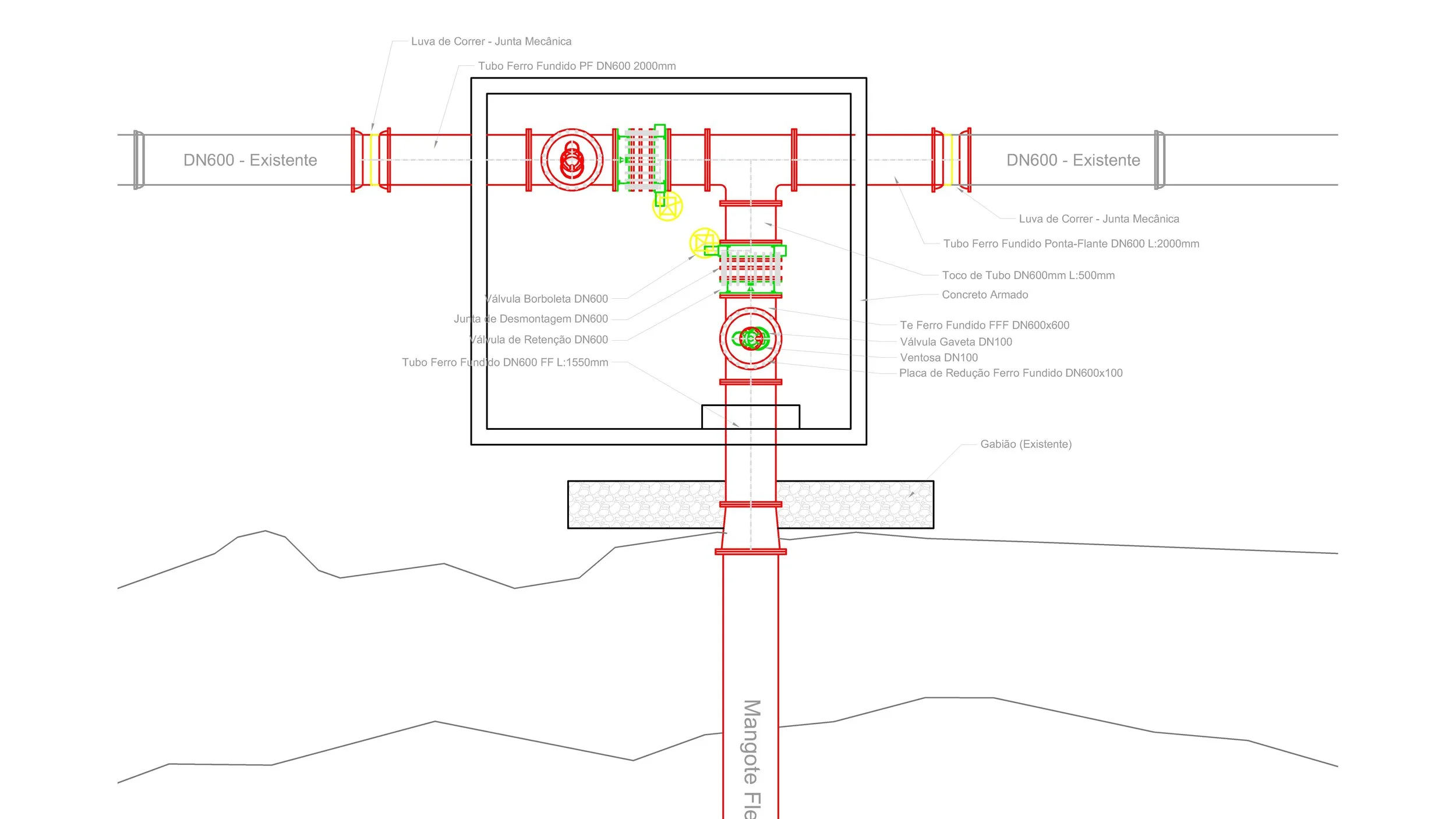

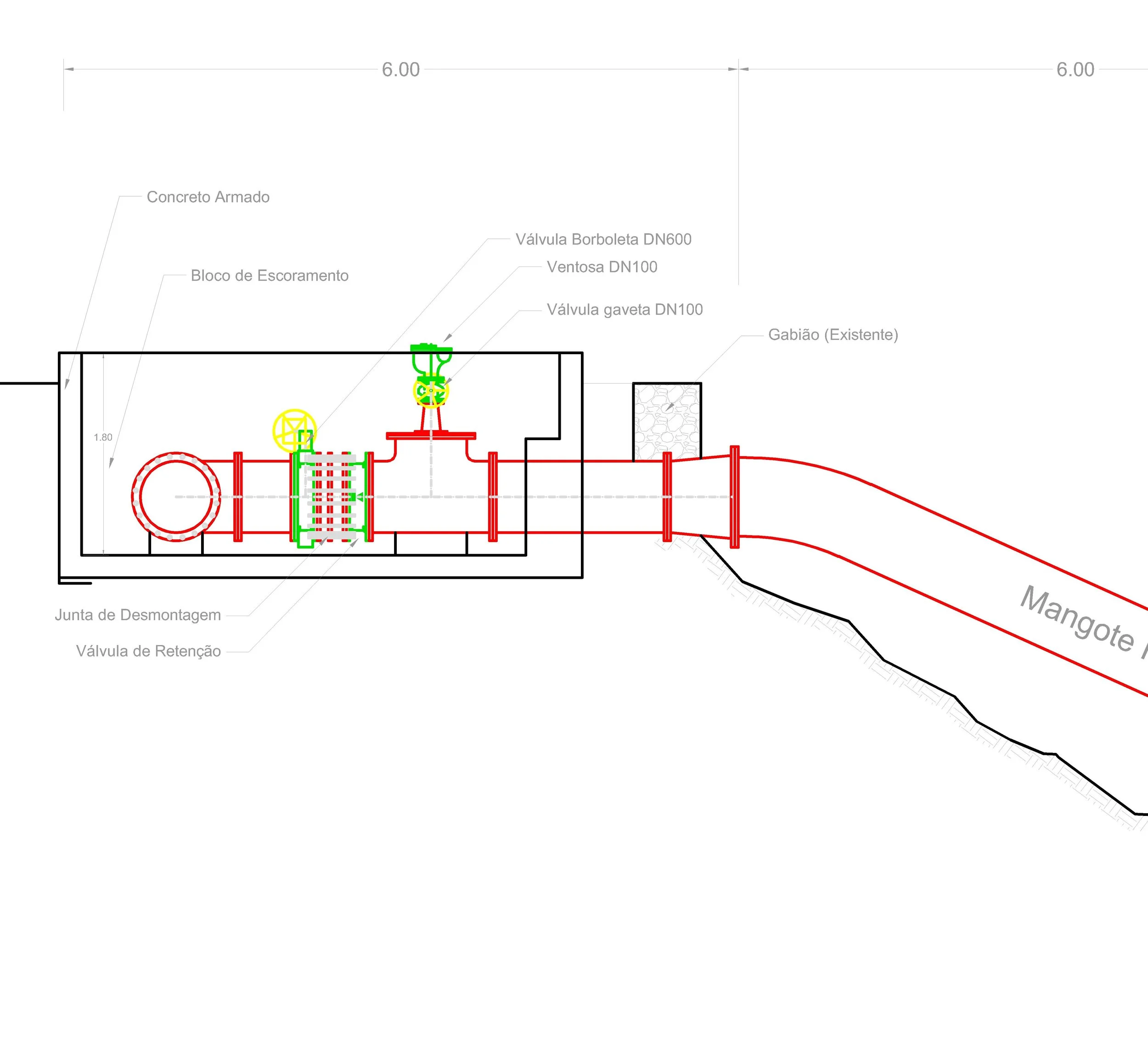

Installed a new fiberglass floating intake unit connected by a DN 600 flexible line. Built the riverbank works, including foundations, anchors, valve assembly, and accessories, and completed the mechanical and hydraulic tie-ins.

Challenges:

Kept the installation as far landward as practicable to avoid bank instability during construction and operation.

Fast-acting check valves were used due to the unavailability of single/double swing check valves at the time.

Outcome and lessons learn:

The manufacturer-supplied DN 600 flexible line performed as intended, but market availability is limited; securing spares or specifying an alternate standard product is advisable.

A tee for check-valve access functioned well for maintenance, though removing blind flanges is slow; consider quick-release closures on future designs.