Overview

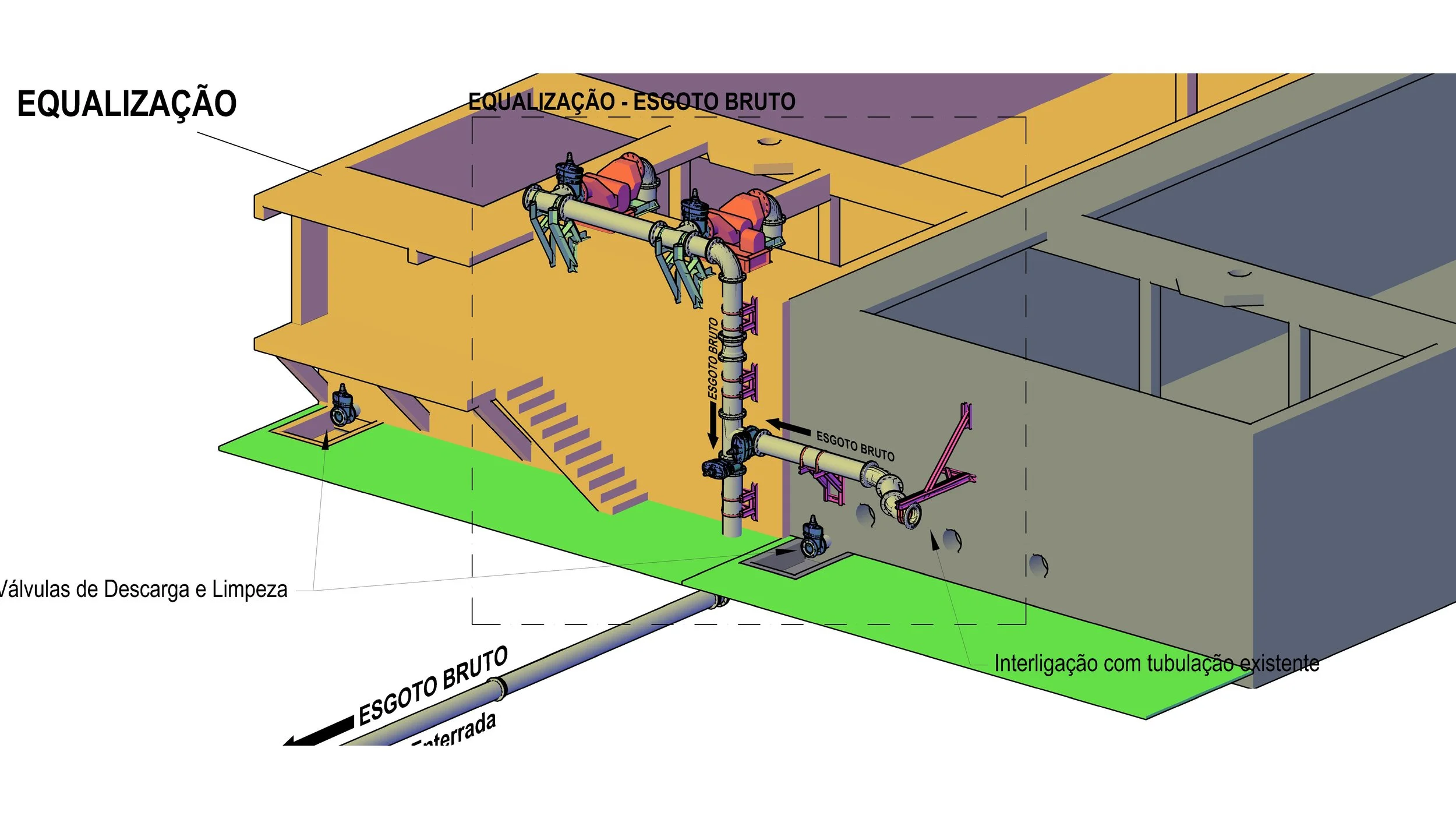

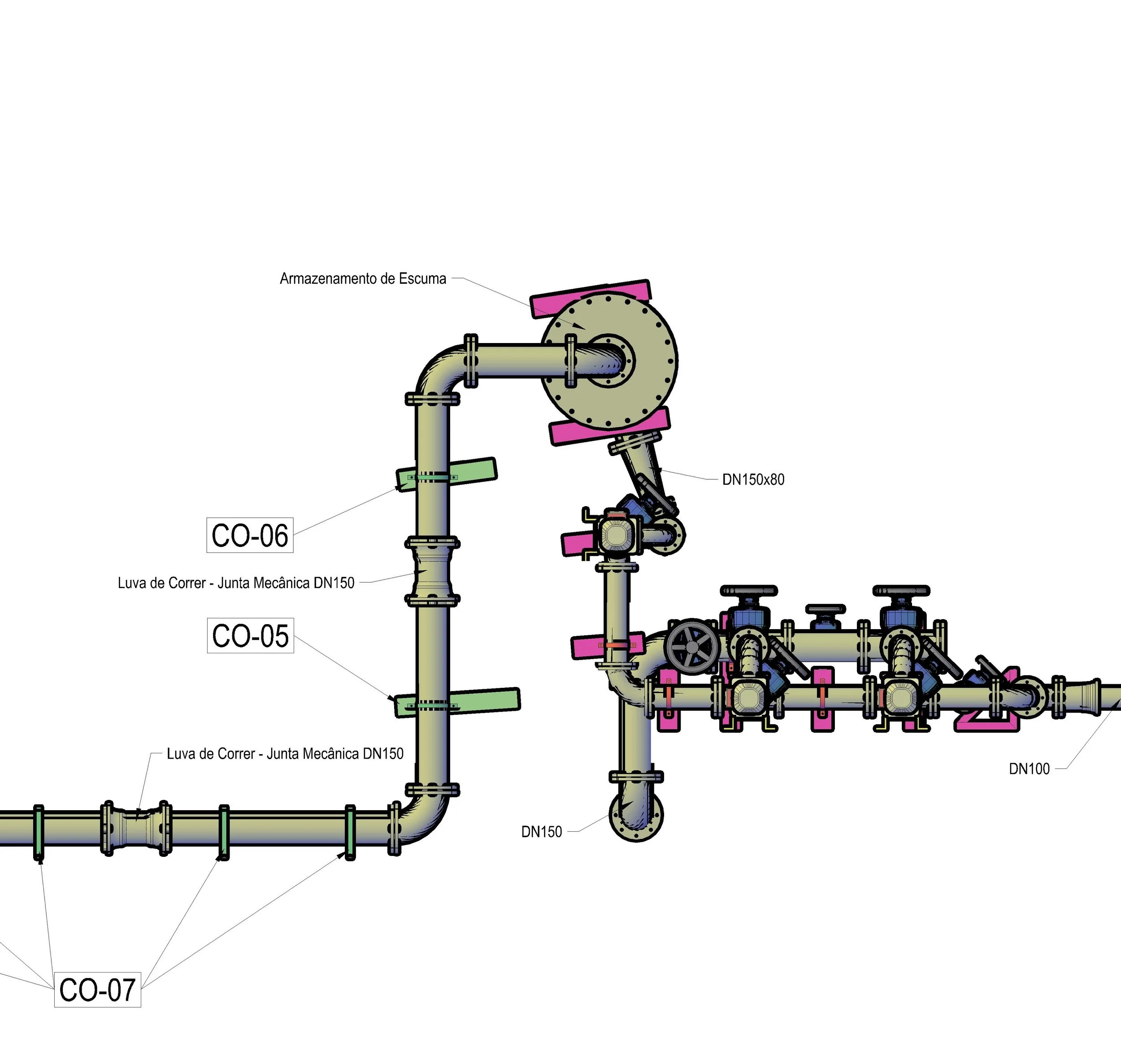

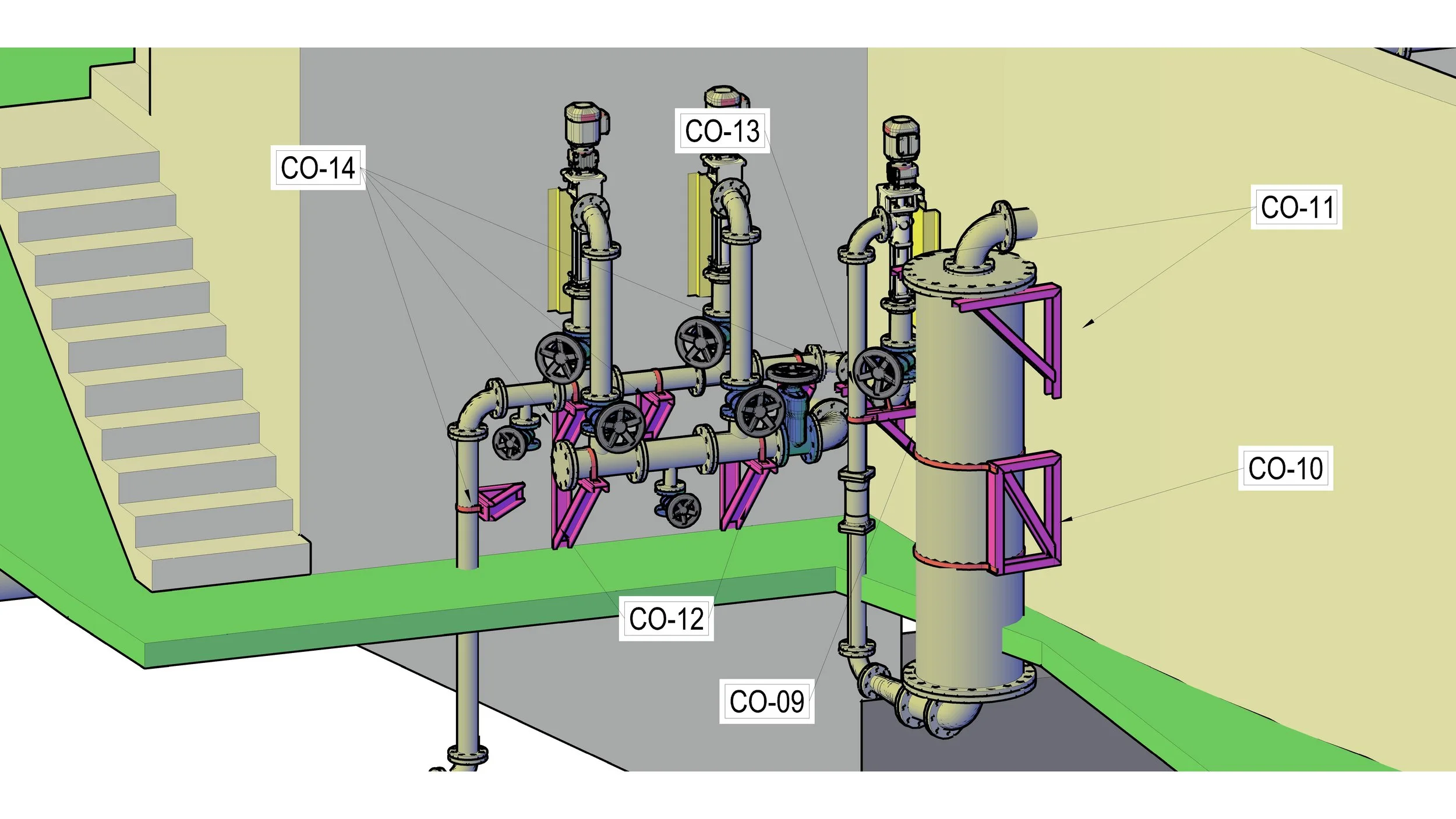

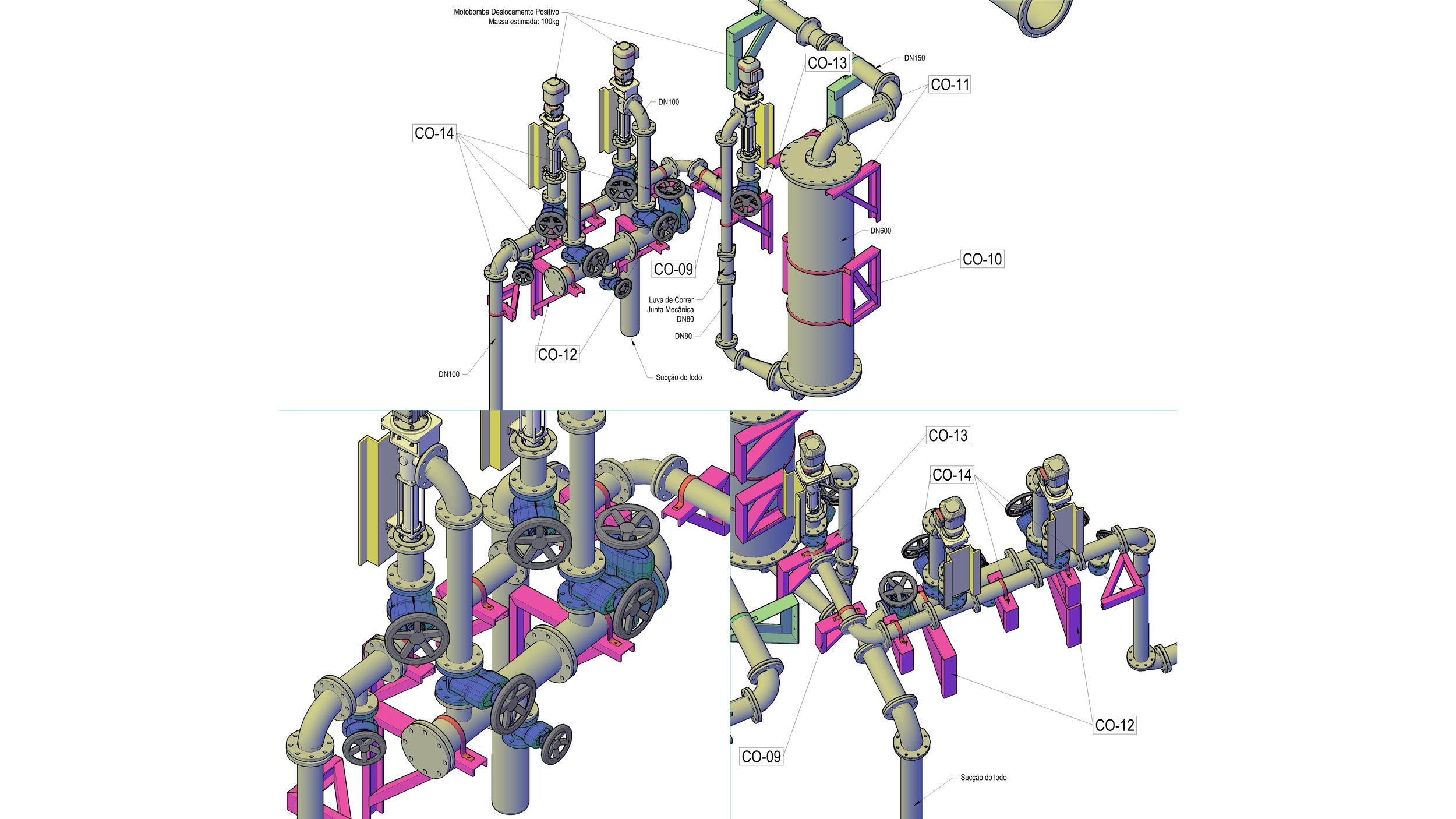

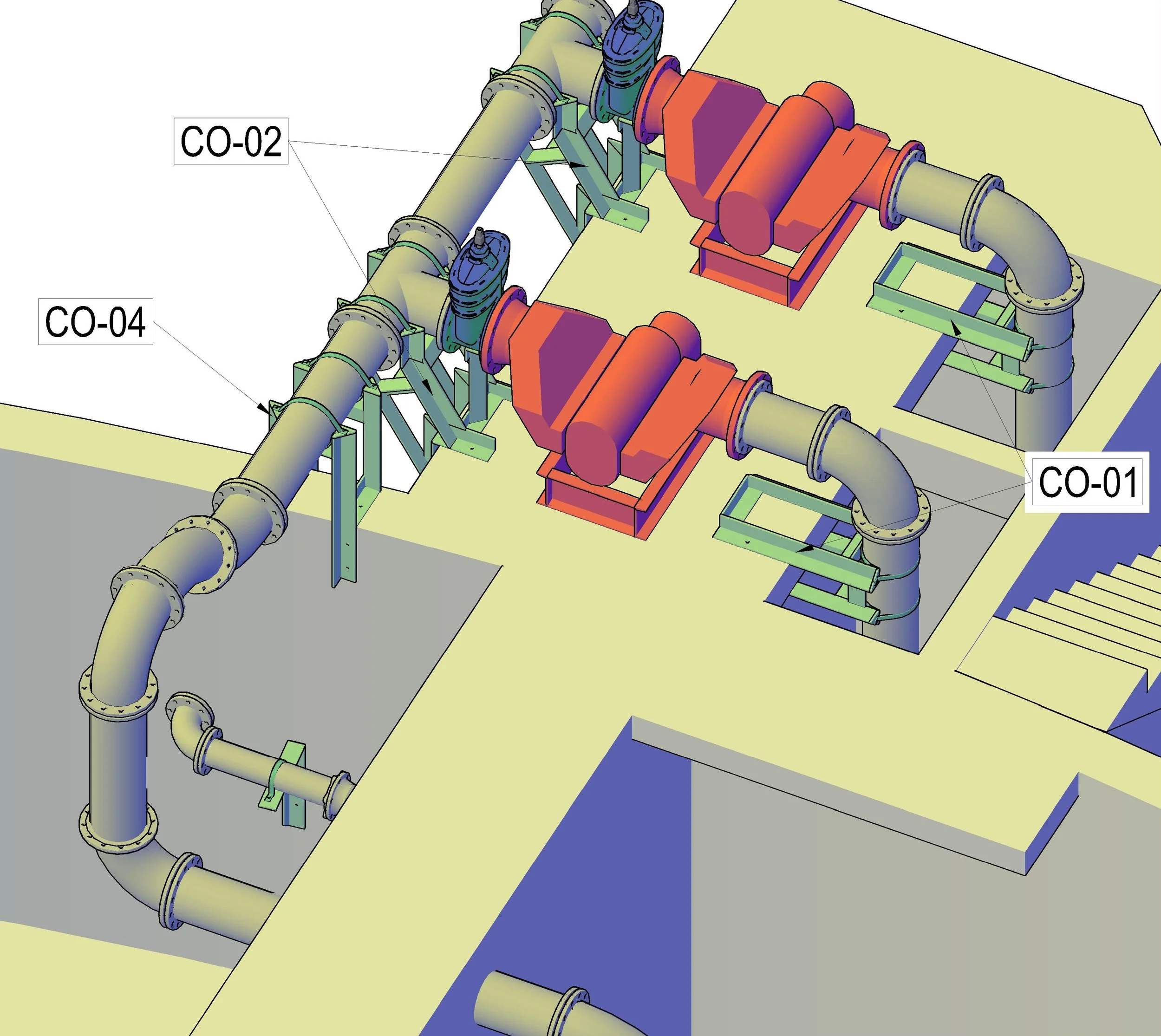

Designed, produced the full technical package, and supervised structural modifications and piping installation for a 130 L/s wastewater treatment station (WWTS) module—Module II. The scope included adapting the concrete structure, installing a new piping layout, and integrating new pumps and valves to resolve persistent clogging observed in Module I, while maintaining continuity of operations.

Requirements and challenges:

Use “lobular” pumps instead of centrifugal to reduce the constant clogging experienced in Module I.

Install all pumps and equipment above the flood level to protect assets.

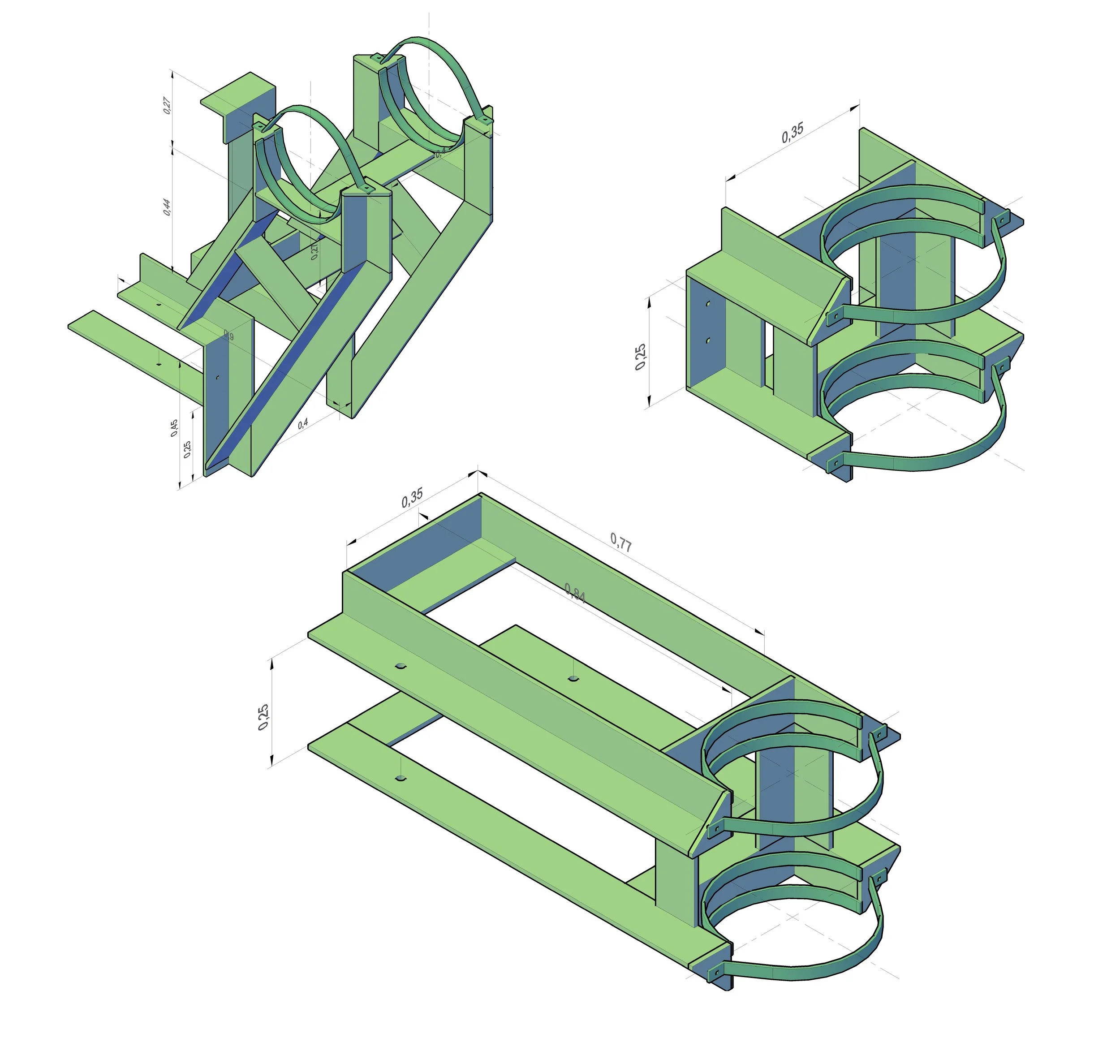

Work within an existing concrete structure, requiring fit-for-purpose structural modifications.

Hydraulically connect two equalization tanks that remained in operation during the works.

Outcome and lessons learned:

Clogging and maintenance were reduced by adopting lobular pumps.

The new layout increased operational flexibility for maintenance and process control.

Cast-iron fittings (vs. welded steel) are expected to extend service life and simplify future replacements.